Hi Guys,

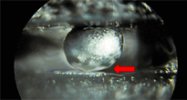

I have been using a 15W from maplins, and it is feckin useless. I managed to get in a right tis while attempting a RGH on a slim. I now have a big blob of solder I cant melt to soak it up with wick.

So my question is for you guys, What is the best soldering Iron to use. I don't want a gas one lol.

Any links would be good?

Cheers,

JohnO

I have been using a 15W from maplins, and it is feckin useless. I managed to get in a right tis while attempting a RGH on a slim. I now have a big blob of solder I cant melt to soak it up with wick.

So my question is for you guys, What is the best soldering Iron to use. I don't want a gas one lol.

Any links would be good?

Cheers,

JohnO