I've now had a chance to actually try a chip remove and replace on some old laptop memory sticks that I had lying around. The chips are smaller in length but the pin count is the same as the flash chip that needs to be replaced.

I didn't take actual pictures of the entire process as it's quite difficult to do unless you have an assistant which I don't

Shown below is the equipment I used:

I had 2 electric solder irons, one with a standard tip and one with a fine point tip. I never actually needed to use the fine point tip iron in the end but I'd normally use that when removing bridges between legs and or for fine soldering. Important tip on the soldering irons is to keep the tips clean and tinned. Tinning just means to keep some solder on the tip, the tip should have a silver finish when wiped, if it goes black then give it a wipe as soldering is all about flowing and a black tipped soldering iron won't let the solder flow freely off on and off the tip. Pictures below show the 2 irons and the tip with solder.

Next in the first picture is a pen knife that I used when lifting one side of the chip, sand paper that I use to clean the tips of the soldering iron when cold, bottle of flux liquid, de-soldering copper braid, solder, gas powered soldering iron which has a catalyst function (more about this later), a de-soldering pump and 2 bits of laptop RAM. Now I do have other equipment but have chosen the above to show how to do it and that it can be done with what I've used.

The gas powered soldering iron has a catalyst function, this means that it can act like a hot air soldering iron, can't accurately control the temps but it can blow either a naked flame or hot air as shown in the picture below:

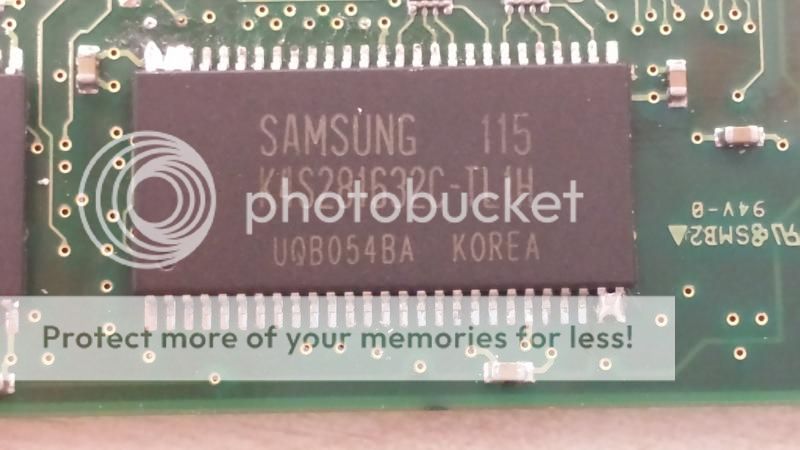

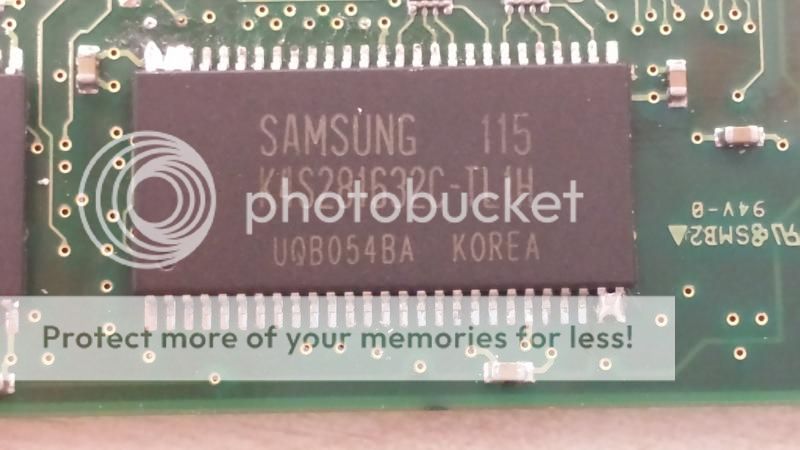

This is a close up of the memory stick that I'll be using:

In order to remove the chip I first fluxed both sides of the chip, you don't strictly need to do this when removing but I did this to stop any tarnishing of the joints or legs whilst I had heat applied on the chip. I heated up one side of the chip gently going up and down the legs with the gas powered soldering iron; if you look closely you'll see the existing solder on the legs change colour, when this happened I used the penknife to gently lift up that side of the chip so that it clears the pads of the PCB. You have to be gentle, exert any force and you might end up ripping the pads/tracks off the PCB. Shown below is a picture of one side of the chip lifted. Again don't lift the chip too high off the board, remember that the other side is still soldered.

Repeat this for the other side, again apply the heat, don't keep the heat in any one place for too long and when the solder appears to change colour lift off the other side. Here's a picture of the chip removed, you can just make out that the pads on the board have solder on then in peaks/bumps, now you can leave this as is but I used the de-soldering copper braid to remove the remaining solder off the pads and generally tidy up, this makes it much easier when aligning the replacement chip, bumpy pads and the chip won't sit properly and may move around.

Again with the de-soldering copper braid, there should be no forced movement. I cut a piece of braid, put the end of the braid on the board and applied heat using the electric soldering iron with the flat tip until the solder melts and starts to flow then gently run the braid with the iron and heat applied up and down the pads mopping up the solder. If the braid gets stuck anywhere do not pull, apply heat to melt the solder and free it.

Here's a picture after I've cleaned the pads:

You're now ready to replace the chip, at this point I put some flux onto the pads but you don't really need to at this point but the reason I did was so that the liquid flux would help to hold the chip in place once it had been aligned, I'm convinced it helps which is why I applied it. Once the chip is in place I then tacked it by soldering a couple of legs of the chip on opposite ends of the chip as shown in the picture below:

I then reapplied the liquid flux to both sides, liquid flux is important as it stops the pads and legs from tarnishing which means the solder flows freely and it also helps to dissipate and distribute the heat. I then used the drag method of soldering, so I used the flat tipped electric soldering, cleaned the tip so that it was silver, applied the iron to the legs where I'd tacked, added some solder and then dragged the iron down the legs. Don't apply any more solder and keep dragging the iron down the legs, drag it in one direction only. There are plenty of videos on YouTube on this method so do a search and watch a video or 2. I then repeated this for the other side. I did end up with bridged legs so I applied some more flux and continued dragging the iron a few more times per side, if the bridges don't go then don't worry, for me both side still had bridged legs as shown below:

In order to remove the bridges you can either use the de-soldering copper braid to mop up excess solder or do what I did and use the de-soldering pump. Reason I chose the pump is that my soldering irons don't really get hot enough for easy use with the copper braid. For the pump, make sure the soldering iron tip is nice clean and silver, apply heat when the solder melts, use the pump to suck off the excess solder, repeat until all the bridges have been removed. I then once again applied liquid flux and then performed the drag on the legs on both sides but this time in alternate directions just to even out all the joints and solder.

You finally end up with this which is the chip soldered back in place:

I am going to re-iterate what I've said before and that is that this isn't an easy task, you need the right equipment and you definitely need the liquid flux, some will say poo-poo but having the right equipment will make the job much more easier.

Any questions, if I've made a mistake or want more clarification then fire away.